A Faraday Mirror is a fiber optic polarization rotator mirror that is used for making a wide range of passive fiber optics components. It is an important invention that made it possible to create passive polarization-maintaining components.

Earlier, the main issue was to maintain the state of polarization as the beam travels across the fiber. This can be easily achieved by using a polarization-maintaining (PM) fiber which is designed for the very same purpose. However, PM fibers and PM-fiber-based devices used to be extremely expensive for many applications and were also difficult to handle.

An optical beam that travels in a typical single-mode (SM) fiber undergoes random changes in birefringence due to stress, vibration, or temperature variation. The use of the Faraday rotator mirror can help resolve this issue.

What is a Faraday mirror?

A Faraday mirror is a fiber optic device that can be used for both the reference mirror and the probing mirror. It works as a phase conjugate mirror by introducing a phase delay of 90 degrees. This feature allows the mirror and the return path of the optical beam to compensate for any induced birefringence automatically.

What is a Faraday mirror made of?

A high-quality Faraday mirror is made of Terbium Gallium Garnet (TGG). TGG is a crystal that is currently the best magneto-optical material for Faraday rotators and isolators. It is considered best because of the high Verdant constant and superior Faraday Effect. It has a higher thermal conductivity and high resistance to laser damage.

How does a Faraday mirror work?

A Faraday mirror works based on the Faraday Effect. In this device, a non-reciprocal rotation of a polarization state occurs as the light beam passes through a special optical medium under the effect of the magnetic field. We will discuss its working with the help of Faraday rotator as its main application is this device.

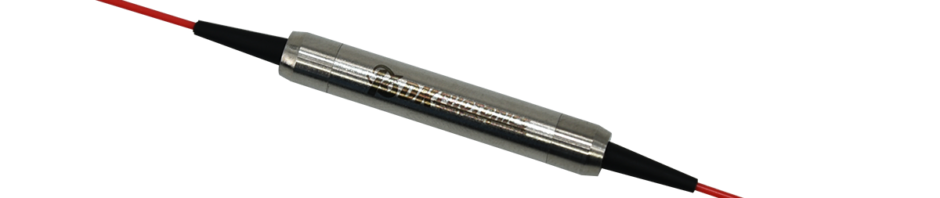

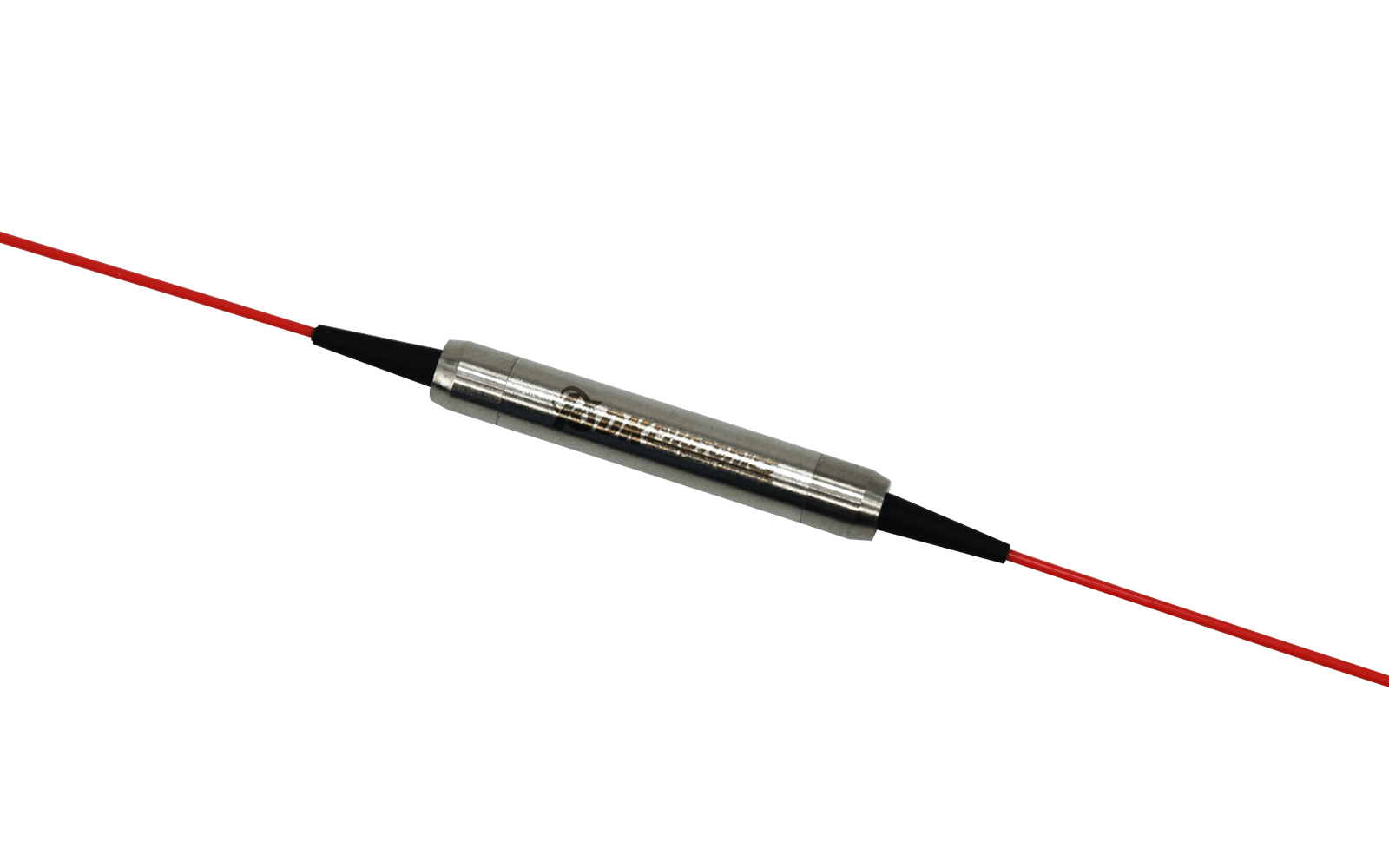

A Faraday rotator mirror (FRM) consists of a fiber collimator, Faraday rotator, and mirror.

As the orthogonal wave light components pass the optical fiber in the forward direction, they will experience a rotation of 45 degrees in the clockwise direction. When they are reflected by the mirror, they pass the Faraday rotator again, which is a non-reciprocal device, and the polarization state of the reflected optical signal will experience a rotation of another 45 degrees in the same direction as the input signal. Hence, the resultant rotation is 90 degrees. Now, the orthogonal components pass the fiber back but in a complimentary fiber axis and you obtain a linearly polarized light on the close end of the fiber with a rotation of 90 degrees.

Do you need Faraday mirrors to manufacture your fiber optics components or for your research projects? You can easily buy it online at DK Photonics.