Pump Combiner is a passive component, widely used in different applications such as fiber laser, fiber amplifier, high power EDFA, biomedical systems, sensor systems, and more. They are made using the Fused Biconical Taper (FBT) technique. According to their design principle, several pump fibers are arranged around a signal fiber and the whole bundle that is typically surrounded by a glass tube is tapered down in a way that its dimensions align perfectly with that of the active fiber.

Pump combiners are available in three different constructions, namely:

- Multimode NX1

- (N+1)x1 Pump and Single-mode Signal Combiners

- (N+1)x1 Pump and PM Signal Combiners

- Multimode Pump Combiners

Multimode Pump Combiners are usually the ones that couple 7 or 19 multimode sources directly into cladding-pumped fiber. They combine the optical power from different optical fibers to create a high power output.

Multimode combiners facilitate highly efficient power transfer to cater to the needs of high-power applications like direct diode material processing and pump cascading while ensuring maximum brightness conservation.

The main applications of multimode pump combiners are fiber lasers, fiber laser combination, industrial, and research. They are available in different configurations of N x 1, such as 2×1, 3×1, 4×1, 7×1, 19×1, 37×1, and so on.

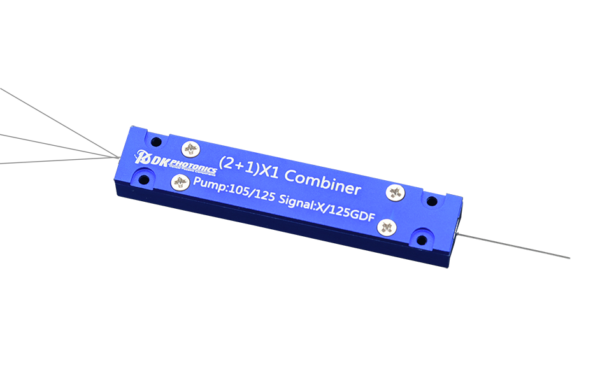

- (N+1)x1 Pump and Single-mode Signal Combiners

These types of combiners are designed to couple 6 or 18 multimode sources and 1 SM signal source either to provide a combined power output or to use with a cladding-pumped fiber.

In other words, single-mode combiners are those pump combiners where the signal input is transferred via a single-mode fiber and not the pump inputs. Pump inputs are typically used in multimode pump combiners.

The signal-fiber design is often used in the military and medical industries. It can also be used to design an amplifier for use in telecommunications.

- (N+1)x1 Pump and PM Signal Combiners

These combiners are built to couple 6 multimode sources and 1 polarization-maintaining (PM) source to produce combined power output or be used with a PM cladding-pumped fiber. Polarization-maintaining combiners are said to possess polarization-maintaining properties for the signal only.

Just like other pump combiners, they are also used to design amplifiers that require signal polarization outputs for use in industrial, military, medical and telecommunications applications.

Key Properties to Look for in Quality Pump Combiners

- The diameters of fibers should be the same to ensure high-quality fusion splicing with the proper matching of core positions.

- The pump fibers must have high compatibility with fibers of pump laser diodes. The core diameter and numerical aperture must be at least as high as those of pump diodes’ pigtails. While larger values of pump input fibers don’t affect power coupling efficiency, it might mean that the pump brightness won’t be utilized fully.

- The intensity profile of the fundamental signal fiber mode should match the fundamental mode of the active fiber core. It will help you couple signal light into the fundamental mode efficiently.

- The pump light should suffer minimum losses when propagating through the combiner. It will help ensure a coupling efficiency higher than 90 percent and minimized thermal damage.

- In a pump or signal combiner, there should be only a minimal loss of brightness.

- The combiner should withstand the intended optical power levels.

Whenever you buy pump combiners, keep all these factors in mind to ensure that you make the right choice. Besides, you also have the freedom to order customized pump combiners. So, if you don’t find the pump combiner you are looking for, don’t hesitate to get in touch with the manufacturer and discuss your requirements.