A Polarization Maintaining Tap Coupler is a special device used in fiber optic systems. It helps split or combine light signals while making sure the light stays in its original state, called polarization. But there are several things that can make a Polarization Maintaining Tap Coupler work better or worse. What are these factors that affect the performance of polarization maintaining tap couplers? Let’s take a look at seven of these important factors.

But before we begin, let us look at how these Polarization Maintaining Tap Couplers work.

How Do Polarization Maintaining Tap Couplers Work?

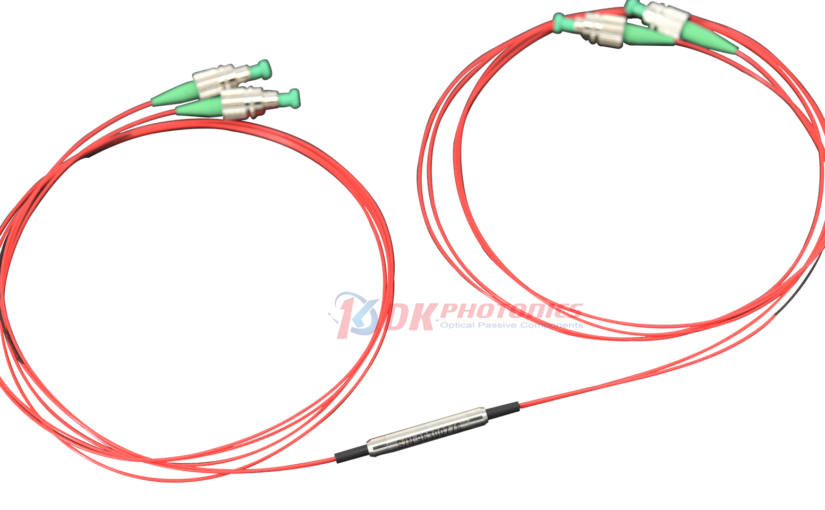

Polarization Maintaining Tap Couplers are made up of special fibers that have a unique structure that allows them to maintain the polarization of the light passing through them.

When light enters the coupler, it is split or combined while preserving its polarization state. This is important for applications where the polarization of the light signal needs to be maintained, such as in fiber optic sensors or specialized communication systems.

The Type of Fiber Used

Polarization Maintaining Tap Couplers are made with special fibers that can keep the light in its polarized state. If the fiber isn’t the right type or if it’s not of good quality, the coupler might not be able to keep the light polarized properly.

How It Is Manufactured

Polarization Maintaining Tap Couplers are carefully put together using special techniques. If there are any mistakes or problems during the making process, it can cause issues like too much light being lost or the polarization not being maintained well.

How Much Light It Splits or Combines

The coupler needs to split or combine the right amount of light for what it’s being used for. If it’s splitting or combining too much or too little light, it won’t work as well as it should.

The Environment Around It

Factors like temperature, humidity, and vibrations can affect how well a Polarization Maintaining Tap Coupler works. Very hot or cold temperatures, or too much moisture in the air, can make the fibers inside the coupler change shape a little bit, which can mess up the polarization. Vibrations can also cause problems.

How It Is Packaged or Protected

The way the Polarization Maintaining Tap Coupler is packaged and protected can also make a difference. If the packaging isn’t good enough, it might not protect the coupler from factors like temperature changes or vibrations, which can make it not work as well.

How It Is Connected to Other Parts

In many fiber optic systems, the Polarization Maintaining Tap Coupler needs to be connected to other parts. If these connections aren’t done correctly, it can cause problems like the fibers getting misaligned or stressed, which can affect how well the coupler maintains polarization and sends light.

The Coupling Ratio

The coupling ratio is how much light the coupler splits or combines. Different uses might need different coupling ratios. If the ratio isn’t right for what the coupler is being used for, it might not work as well as it should.

In order to ensure that Polarization Maintaining Tap Couplers function as best they can, engineers and technicians should try to understand these seven important factors. They can choose the right fibers, make the couplers carefully, pick the right coupling ratio, protect them from factors like temperature changes and vibrations, package them properly, connect them correctly, and more.