As the demand for fiber optics networks is rapidly growing, more businesses and network service providers are looking for ways to increase the capacity of their networks. One traditional way to increase the capacity of a fiber network is to install more optical fiber cables. However, this can be extremely expensive and thus, limits the ability to cater to the increasing demand for more data and bandwidth.

However, the ongoing research and development in optical passive components have now made it possible to double the network capacity without installing additional optical fibers. The one small component that has made it possible to double the capacity of a fiber network is a high-power circulator.

What are high-power circulators?

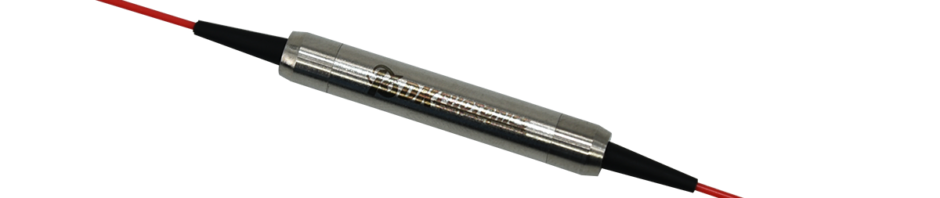

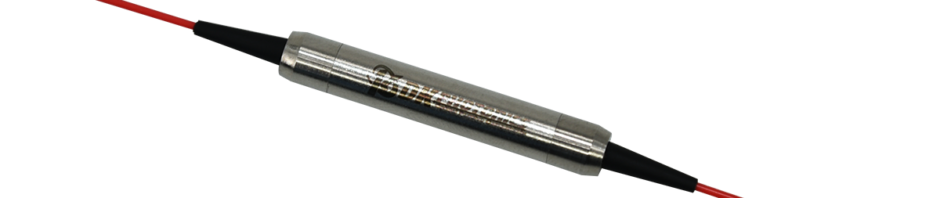

High-power circulators are non-reciprocal optical passive components that route incoming optical signals from one port to the next port while blocking transmission from one port to the previous port. It can handle high levels of optical power and is specifically designed for high-power applications, including communication, fiber lasers, etc.

Some examples of high-power circulators are:

- 100W 1064nm high-power circulators

- 30W 1550nm high-power PM circulators

- 10W 2000nm 3-port high-power PM optical circulator s

How do high-power circulators increase network capacity?

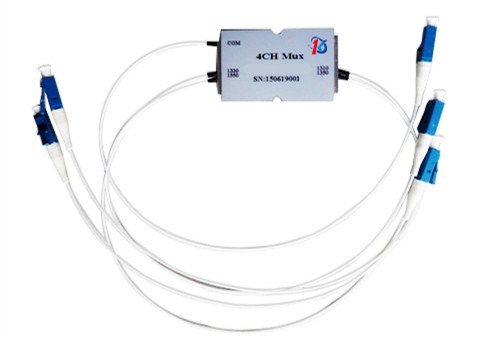

The use of high-power circulators provides the ease and convenience of doubling the transmission capacity of a fiber optic network without requiring optical fiber cables. High-power optical circulators are three-port, non-reciprocating, and unidirectional devices that help you achieve bidirectional propagation of light signals in a single fiber. Besides, they also result in obtaining low insertion loss and low crosstalk between two channels.

Typically, bidirectional optical links can be operated in full-duplex or half-duplex mode. In full-duplex, optical signals can be sent and received simultaneously. On the other hand, in half duplex mode, optical signals can be either sent or received but not both at the same time. A half-duplex transmission can be achieved by using either single or double fibers and a full-duplex transmission is implemented by using two fibers.

However, by using high-power circulators, bidirectional transmission can be done through a single fiber, thus, minimizing the amount of optical fiber needed and maximizing the transmission of optical signals over a single fiber.

As a result, it also helps eliminate the need for more powerful transmitters, more sensitive receivers, and more optical amplifiers, making the whole fiber network more economical. The cost is further reduced because high-power circulators can be obtained at cheaper prices.

To increase the isolation and extinction ratio of optical circulators, birefringent crystals, such as Terbium Gallium Garnet (TGG), are used to design these components.

Multi-port high-power circulators, such as 3-port high-power circulators, act as a roundabout for light where each input port is routed to exactly one output port in a non-reciprocal fashion. As a result, integrated circulators can double the network capacity in many data centers and telecommunication networks.

At DK Photonics, you can buy a wide range of high-power circulators, such as TTG-based 1064nm high-power circulators, 1030nm high-power circulators, 1080nm high-power circulators, and more. If you don’t find the specifications you need for high-power circulators for your application, please feel free to contact us.