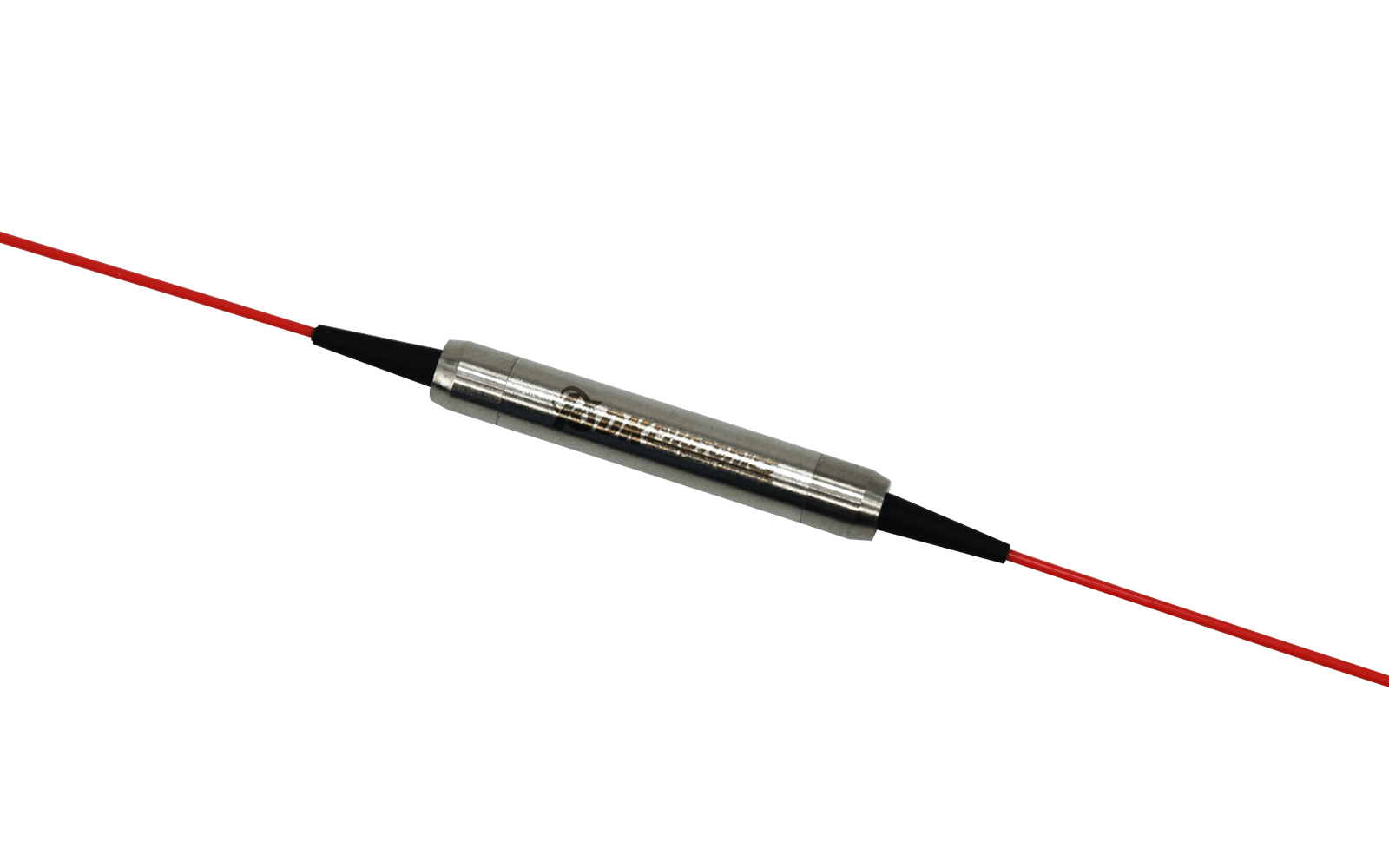

A 2.0μm single-mode fused coupler is an optical passive component designed to split off a portion of light for the purpose of optical monitoring and feedback. In this post, you will learn about the uses of 2.0μm single-mode fused couplers and a lot more.

What are the uses of 2.0μm single-mode fused couplers?

2.0μm single-mode fused couplers are immensely used in fiber amplifier power control and in transmission equipment for performance monitoring and feedback control.

Other important applications of 2.0μm single-mode fused couplers are EDFA, fiber laser, and testing instrumentations.

Apart from splitting optical signals between two fibers, 2.0μm single-mode fused couplers are also used to combine optical signals from two fibers into one fiber.

What is the significance of using fused fibers in an optical coupler?

A 2.0μm single-mode fused coupler is made of 2.0μm single-mode fiber in which only one type of light mode can propagate at a time. The term “fused” represents the construction of this coupler. It means the fiber used in it is designed by stretching, twisting, and fusing the two single-mode fibers so that their cores remain closer to each other.

The method used for fusion provides a simple, rugged, and compact construction to split and combine optical signals.

What is the difference between single-mode fused couplers and multimode fused couplers?

Multimode fused couplers are dependent on modes. In a multimode fused coupler, certain modes within one fiber can pass to the second fiber, while other modes don’t. It means the splitting ratio depends on which modes are excited within the fiber.

On the other hand, single-mode fused couplers transmit only one mode of light. Therefore, they don’t suffer from mode dependency. However, single-mode fused couplers are highly dependent on wavelength.

Even a difference in the wavelength of only 10nm can result in major changes in the splitting ratio in single-mode fused couplers.

Where can I buy 2.0μm single-mode fused couplers?

The 2.0μm Single-Mode Fused Couplers offered by DK Photonics are high-quality and highly reliable because they offer low levels of sensitivity to polarization. It enables them to more effectively monitor and manage optical networks. Besides, its 2.0μm single-mode fused couplers are known for offering low insertion loss, low polarization dependent loss, high stability, and excellent reliability.

At DK Photonics, you can buy 2.0μm Single-Mode Fused Couplers in a broad range of split ratios, lengths, and packaging and can also order these couplers with custom specifications.