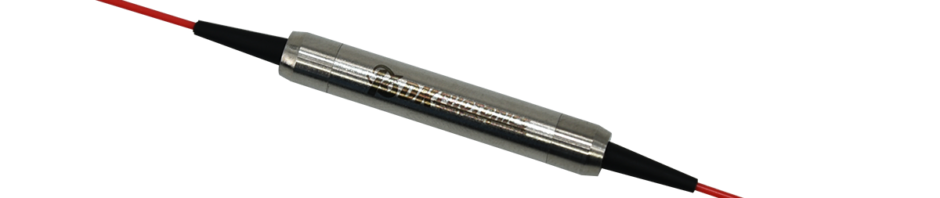

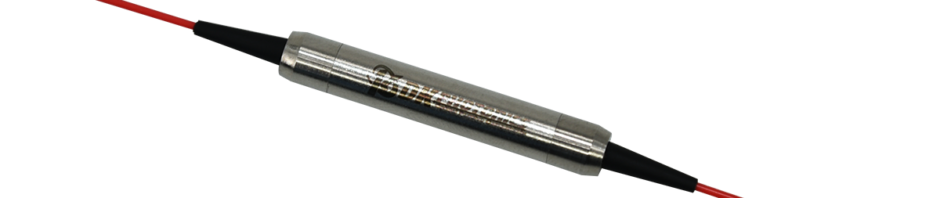

Tell us the name of one common thing that you can find in various high-power components such as high-power optical isolators, fiber circulators, fiber optic attenuators, and CWDM/DWDM modules. All these components have one thing in common and that is called a high-power fiber collimator. In this blog, we will discuss high-power collimators in brief. So, if you want to know what these are and why they are needed, keep reading till the end.

What is a fiber collimator?

The meaning of the term “collimate” means to make light rays accurately parallel. Hence, a fiber collimator is a fiber optic component that is used to help change the diverging light from a point source into a parallel beam.

In other words, a fiber collimator is a simple module that consists of fiber and a lens and its basic function is to produce parallel beams.

Fiber collimators are used to collimate the light at the fiber end and can also be used to couple light beams between two fibers. During the designing process of fiber collimators, utmost attention is given to the accurate adjustment of the fiber and lens so that parallel beams can be obtained.

Another thing you need to know is that the stronger the signal strength the higher the efficiency of the fiber collimator. And the fiber collimators that can handle a huge amount of power are categorized as high-power components.

An efficiently designed high-power collimator is characterized by low insertion loss, high-power handling capability, excellent temperature stability, and small beam convergence. Hence, it is considered an ultra-reliable device.

What is the need for fiber collimators?

In fiber optics applications, it is often necessary to transform the light output from an optical fiber into a collimated beam. For that, a simple collimation lens is considered sufficient. But the end of the fiber must be firmly fixed at a distance from the lens that is usually equal to the focal length. Thus, to make this more convenient in practice, a fiber collimator is used in fiber optics applications that require a collimated beam.

Fiber collimators can also be used for launching light from a collimated beam into a fiber or for fiber-to-fiber coupling where light from the first fiber is collimated and then focused into the second fiber by another collimator.

Another application of fiber collimators is the combination with a back-reflecting mirror and an additional element to achieve desired effects. For instance, you can insert a Faraday rotator to obtain a Fiberized Faraday mirror.

Other major applications of high-power fiber collimators are fiber lasers, fiber amplifiers, instrumentation, and test and measurement.