When two or more optical wavelength signals are combined and transmitted through the same fused fiber core for transferring information, the process is called optical fused WDM, an acronym for Wavelength Division Multiplexing (WDM). In this blog, we will discuss wavelength division multiplexing in brief and see what makes this technology so favorable and popular in today’s time.

An Overview of Wavelength Division Multiplexing

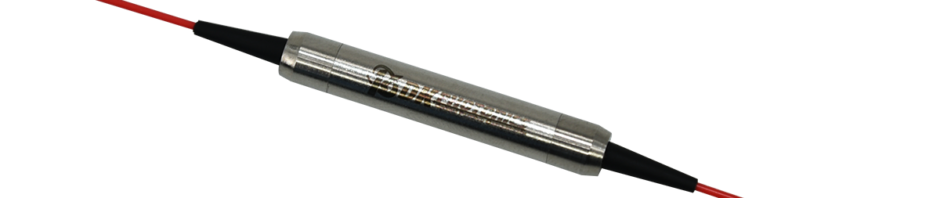

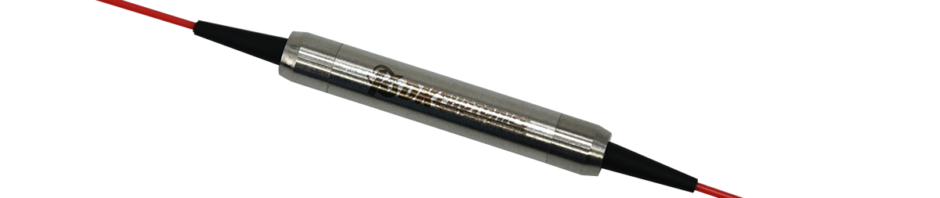

Wavelength Division Multiplexing (WDM) is a technology that is typically applied to wavelength division multiplexers (combiners) and demultiplexers. These combiners and demultiplexers are installed at both ends of a fused optical fiber to combine and split different light waves respectively. The working of both devices revolves around the same principle.

Fused taper, dielectric, raster, and flat are the different types of optical wavelength division multiplexers and their quality is determined by various characteristics such as insertion loss and isolation.

In general, an optical fiber communication line can be divided by using wavelength division multiplexers or demultiplexers. Depending on the number of multiplexing wavelengths, the line can be divided into two-wavelength multiplexers and multiple-wavelength multiplexers. Then, based on the interval between multiplexing wavelengths, it can further be divided into coarse wavelength division multiplexing (CWDM) and dense wavelength division multiplexing (DWDM) that are often used in various WDM systems and optical amplifiers.

How is the optical fused WDM technology beneficial for the optical communication industry?

- It allows the full utilization of an optical fiber’s low loss band to maximize an optical fiber’s transmission capacity.

- It helps increase the physical limit of information transmission via one optical fiber by two times.

- Today, we use only a small part of the optical loss spectrum. The WDM technology can help us make full use of a huge bandwidth of a single-mode optical fiber.

- It is empowered with the ability to transmit two or more unsynchronized signals in the same optical fiber and thus, provides compatibility between digital and analog signals. This ability is independent of the data rate, modulation mode, or allows it to remove or join channels even in the middle of the line.

- WDM technology can be used for the cables that have already been built with few cores and laid early because it ensures the compatibility to make the transmission of multiple one-way or two-way signals possible.

- It helps reduce the amount of optical fiber used and requires fewer fibers to install for a project when compared to old projects before the advent of WDM technology. Thus, it lowers the cost of construction and installation significantly.

- Since WDM technology has reduced the number of optical fibers required for a project, it has become easier and faster to recover from a fault.

- The sharing of active optical equipment also reduces the cost of transmitting multiple signals or appending new services.

- This technology has also reduced the number of active devices used, and hence, also improved the reliability of a system.

With the rising need for the development of integrated cable television services, the demand for increased network bandwidth and optical fused WDM devices is also increasing. What we are facing ahead is the age of optical communication. Thus, there is no doubt that the use of WDM technology will become more common in the future than now.