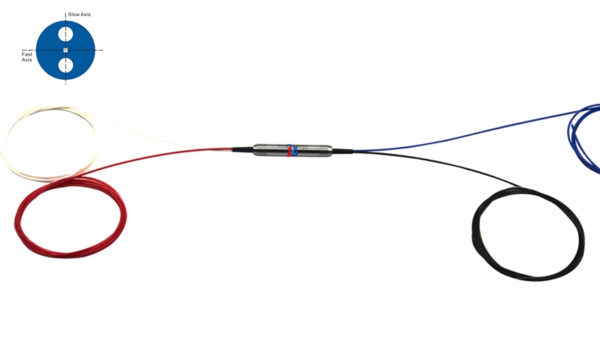

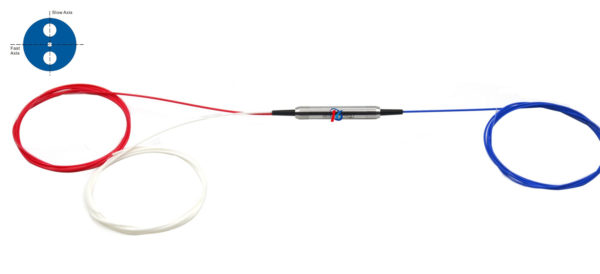

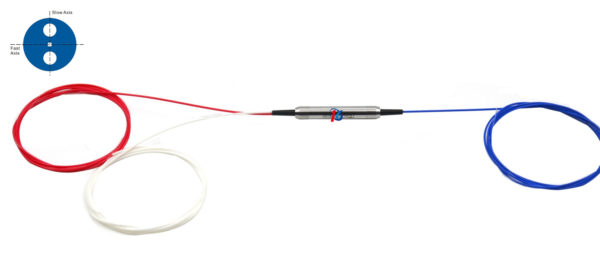

Since several years, Polarization Maintaining Optical Circulator has become an important element in the optical communication system. But these days, its applications have expanded not only in the telecommunication field but also in imaging and medical field.

In this blog, we’ll discuss on Polarization Maintaining Optical Circulator in more detail, but before that let’s know a few basic regarding it.

To begin with, let’s discuss what exactly is an optical circulator?

An optical circulator is mainly a multiple port non-reciprocal passive component. Its function is just similar to that of a microwave circulator, i.e. to transmit the light wave from one port to other with maximum intensity. But, at the same time, it also blocks any light transmission from one port to its previous port. Besides, the entire optical circulator process is based on the non-reciprocal polarization of the Faraday Effect.

What are the features of Polarization Maintaining Optical Circulator?

There are various features of polarization maintaining optical circulator. Mentioned below are a few major ones:

– It has a high stability

– It has a low insertion loss

– It has high reliability

– It has high optical return loss and so on.

How can optical circulators be categorized?

Optical circulators typically can be categorized into two main streams namely:

– Polarization-dependent optical circulator, and

– Polarization independent optical circulator

Polarization-dependent optical circulator is functional only for a light wave with a specific polarization state. This type of optical circulator is used only in some of the applications that mainly include free space communication between crystal sensing and satellites. Whereas the polarization independent optical circulator is independent of the polarization state of light. In the ordinary circulators, the polarization is certainly not maintained, however, there are polarization maintaining optical circulators available, so they can be used on behalf of it.

Besides, they can also be utilized in a wide variety of applications, but depending on its functionality, optical circulators may be divided into two groups:

– Quasi circulator: In this circulator, the light passes through all the multiple ports, but the light from the last port is lost.

– Full circulator: In this circulator, the light passes through all the multiple ports in a full circle.

When it comes to circulator’s design, there are many variations, but, all the non-reciprocal rotation designs certainly share the same structure with at least three functional elements namely- non-reciprocal polarization rotation elements, polarization recombining, and splitting elements, as well as polarization dependent beam steering elements.

Finally, we can say that with the large development of advanced optical networks and elements, the application of optical circulators are rapidly growing and new and advanced applications and functionalities are emerging quickly.