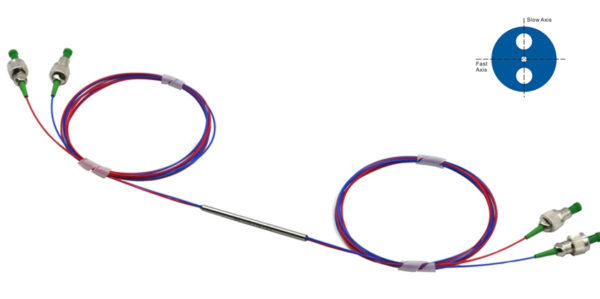

Fused Coupler is a type of optical fiber that is used to split high power single line polarized light into multiple directions without disturbing the line at the state of polarization. This fiber is also used as a power tap to monitor signal power in a PM fiber system. A fused coupler is widely used in PM fiber interferometers, power sharing in polarization sensitive systems, and signal monitoring in PM fiber systems.

Couplers are generally divided into two categories- passive couplers and active couplers. The passive couplers are able to redistribute the optical signal without making optical to electrical conversion while active couplers electric devices used to split or combine signals electrically using a device called fiber optic detector and sources for input and output.

Based on applications, the couple has different types. So to make sure you choose the right coupler, it is crucial to know about them. Here, we will shed light on some of the most important ones that are widely used today.

T coupler

Also, called Y coupler, it is a three port device and mainly used for power monitoring. It is also used for splitting the power input into two equal outputs.

Tree coupler

Its main work is to split the single input into multiple outputs. It is used as a combiner to combine multiple output signals.

Star coupler

It is pretty well different from the first two. Unlike them, this coupler has multiple inputs and multiple outputs. The fibers radiate from the central point likes a star. And this is why it is called star coupler.

Wavelength selection coupler

Also known as WDM (wavelength division multiplexer, wavelength selection coupler splits the signal based, not on power.

Having a look at the types of couplers and their applications, it is quite clear that each of them has a different application. And so they perform well in a particular situation and meet a particular need. If you are looking a coupler, it is very important to choose the one that best meets your needs.

And the best way to know which one will work best for you are looking at your needs. Yes, first of all, you should figure out your requirements. This will make it easy for you to come out with the right option without wasting your time.

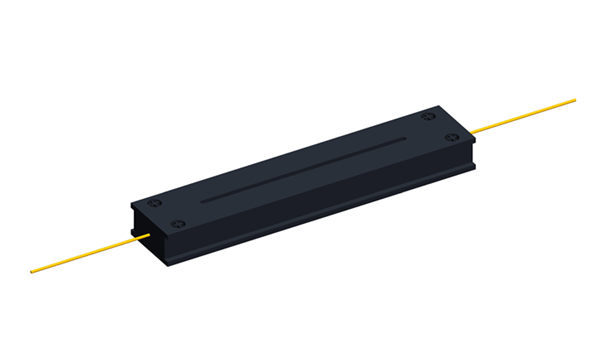

Features of top couplers for polarization-maintaining

In addition to the types of a coupler, the features of coupler also play a vital role in selecting. Here are some of the top features that you must consider when looking for the one for you. A quality fused coupler has:

Low insertion loss

• High extinction ratio

• Compact In-Line Package

• Available for Slow or Fast Axis Operation

• High Stability and Reliability

Whether you are looking for couplers for the use of Fiber Optic Instruments, Fiber Amplifiers, Fiber Sensors, or Coherent Detecting devices, choose the one, keeping in mind the above features. Also, make sure to buy only from top suppliers of Polarization Maintaining Fused Couplers in China.