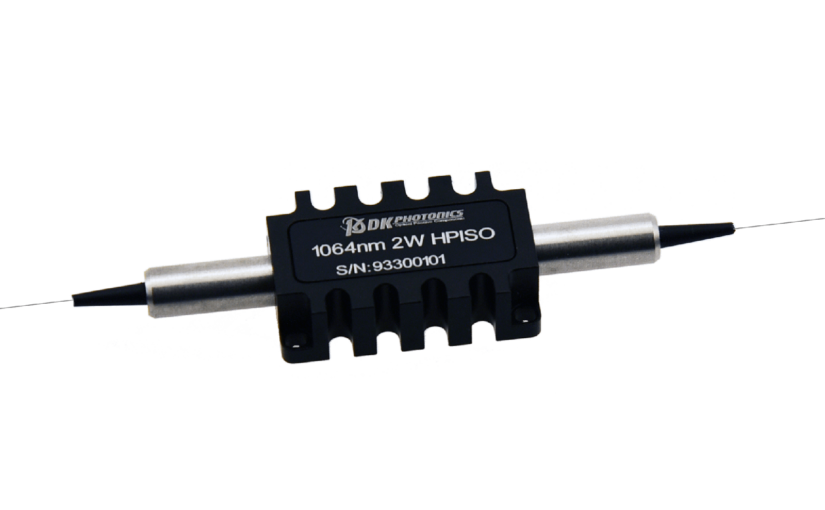

In fiber optics, getting things right is extremely important. Whether you’re working with fiber lasers, scientific instruments, or anything that needs high-power light transmission, having the proper components can make a huge difference. One such component is the 1064nm High Power In-line Optical Isolator -2W – a compact and powerful little device designed to ensure top performance in your fiber optic setups.

What exactly is this 1064nm High Power In-line Optical Isolator -2W thingy?

Simply put, it’s a device that lets light travel in one direction while blocking it from going backward. This feature is important for controlling unwanted reflections or feedback from messing with sensitive optical components like lasers or amplifiers.

While traditional isolators are made from TGG (Terbium Gallium Garnet) crystals, this one is constructed using Faraday crystals. Not only does this make it more compact, but it also allows it to handle higher power levels. It can operate within a wavelength range of ±5 nanometers around the central 1064nm wavelength, making it ideal for high-power fiber laser and instrumentation applications.

But What Makes This Isolator So Special?

Let’s break down its technical specs:

Central Wavelength: It isdesigned to work at 1064 nanometers – a common wavelength for fiber lasers and instruments.

Wavelength Range: While centered at 1064nm, it can operate within ±5 nanometers, ensuring compatibility with various systems.

Isolation: This device offers up to 35 decibels (dB) of isolation, with a minimum of 28 dB within its operating range at 25°C. That’s high blocking power.

Insertion Loss: This refers to how much light is lost as it passes through the isolator. This device has a typical loss of 1.7 dB at 25°C, with a maximum of 2.0 dB at 25°C and 100 milliwatts (mW), 2.5 dB at 25°C and 1 watt (W), and 3.0 dB between 0°C and 50°C with 2W of power.

Polarization and Extinction: For single-mode fibers, the maximum polarization loss is 0.15 dB, ensuring minimal signal distortion. For polarization-maintaining fibers, the minimum extinction ratio is 18 dB (Type B) or 20 dB (Type F), ensuring efficient polarization maintenance.

Power Handling: This little device is a powerhouse. It can handle continuous wave (CW) powers of up to 1W or 2W, depending on the model. And for nanosecond pulses, it can withstand peak powers of up to 5 kW or 10 kW, making it perfect for pulsed applications.

Fiber Types: It is compatible with various fibers, including single-mode (e.g., 1060-XP, 10/125) and polarization-maintaining fibers (e.g., PM980-XP, PM1060L, PM 10/125 DC).

Temperature Range: It can operate between 0°C and 50°C, ensuring reliable performance in different environments.

With specs like these, it’s no wonder that 1064nm High Power In-line Optical Isolator -2W is a valuable component in high-power fiber optic applications across multiple industries:

Applications of 1064nm High Power In-line Optical Isolator -2W

Fiber Lasers:

These lasers are used in marking, cutting, welding, and material processing, depend on the high power handling and reflection prevention of the isolator for steady, effective operation.

Instrumentation:

In spectroscopy, interferometry, sensing, and other instrumentation setups, the isolator maintains signal integrity and prevents feedback for accurate, reliable measurements.

Telecommunications:

While designed for high power, isolators also prevent reflections and maintain signal quality over long fiber optic links.

Scientific Research:

High-power lasers and sensitive components in labs benefit from the isolator’s protection and reliable data collection.

Medical Applications:

In laser surgery, therapy, and other medical procedures involving high-power lasers, the isolator enhances safety and effectiveness by preventing back-reflections.

No matter the application, the 1064nm High Power In-line Optical Isolator -2W is a versatile component that can boost the performance and reliability of your fiber optic systems.

This compact and high-performance isolator offers exceptional isolation, high power handling, and compatibility with various fiber types. If you’re working with fiber lasers, instruments, or any application requiring precise optical transmission, this isolator is a must-have addition to your toolkit. With its robust design and extensive technical capabilities, it ensures optimal performance and reliability, even in the most demanding environments.