The demand for PM fiber components is increasing and is expected to increase beyond 2023, especially in the telecom and mobile industry. And there are many reasons for this increasing demand. First and most important, the performance of PM fiber components in different applications for different industries. The components, no matter how they are used, increase the efficiency and effectiveness of the processes used in.

The PM fiber components are useful but many people still don’t know everything about them. And due to a lack of knowledge, they miss out on several benefits.

In this post, we will discuss some important details about PM fiber components.

What are PM fiber components?

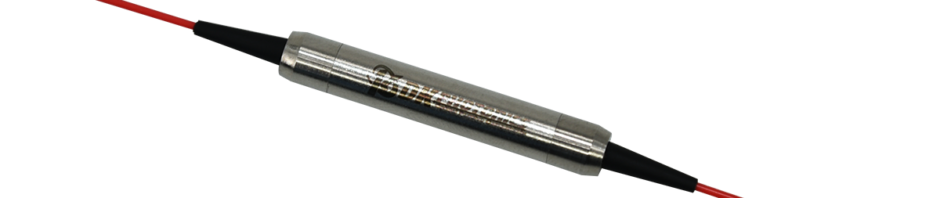

With the strong built-in birefringence, the polarization-maintaining (PM) fiber is a special fiber that preserves the properly oriented linear polarization of an input beam. The optical fibers usually exhibit some degree of birefringence even when they have a circularly symmetric design. This happens because some mechanical stress or other effects that break the symmetry is always there.

The polarization of light that propagates in the fiber gradually changes in an uncontrolled way and depending on wavelength. The uncontrolled way depends on any bending of the fiber and its temperature. For some fiber optic components, the polarization-maintaining feature is extremely important. One of those PM fiber components is modulators.

What is the principle of PM fiber components?

The polarization state is preserved even if the fiber is bent because the polarization of light launched into the fiber is aligned with one of the birefringent axes. There is a strong principle behind this.

The principle is understood as coherent mode coupling. The two polarization modes’ propagation constants are different because of the strong birefringence. This leads to a rapid drift away from the relative phase of the co-propagating mode.

The difference between the relative phase of the co-propagating mode matters. Large differences impact the usual disturbances in the fiber. They vary too slowly to do effective mode coupling.

What are the applications of PM fiber components?

The components are used in applications like fiber optic sensing, interferometry, and slab dielectric wave-guides. Other than this, they are used in telecommunications to connect source lasers and a modulator. Here, the modulator needs light as input.

The components are used in transmission applications like transmission lines for optical sensors and coupling for optical-electrical integrated circuits. In these applications, the polarization plane of the optical signal is important.

The components are used lithium modulators, Raman amplifiers, and other polarization-sensitive systems. These components help the systems to maintain the polarization of the incoming light and keep cross-coupling between polarization modes at a minimum.

Where will you get the best PM fiber components?

Come to DK Photonics, where you will get all kinds of PM fiber components, including 80um PM fiber components. Other than this, you will get customized components, suitable for all your needs.