In this post, we will first explain what optical fiber is and its types in brief and then discuss the role of optical fibers in fiber optics applications and in PM components.

What is optical fiber?

An optical fiber is a thin, hollow, flexible, and transparent tube-like wire that is either made of glass or plastic and is designed to transmit light signals. It facilitates the transmission of optical signals over long distances and at higher bandwidth levels.

Types of Optical Fibers

- Polarization-maintaining (PM) fibers

- Single-mode fibers

- Multi-mode fibers

- Rare-earth-doped fibers

- Highly nonlinear fibers

- Hollow-core fibers

- Multi-core fibers, and more

The Role of Optical Fibers and Their Importance

Fiber optics technology is based on the optical fibers that act as waveguides for light. Think of optical fibers as the fundamental part of fiber optics systems and fiber optics communication applications. Optical fibers carry light signals over long distances which enable engineers to transmit information faster, quicker, and in a more reliable way.

They are intrinsically safe as no electrical signals are involved in transferring data (data is transferred via light). When it comes to bandwidth, no current technology is better than optical fibers as they provide more bandwidth and carry more data than copper cables of the same diameter.

Their performance is not restricted by the cable itself but by the electronic components that constitute the system. The use of optical fibers also leads to a decrease in latency, makes data interception incredibly difficult, and can withstand water and temperature fluctuations. What’s more, they don’t produce any electromagnetic interference.

Thus, the use of optical fibers has literally improved the quality, performance, security, and handling capability of data transmission. That’s what makes optical fibers perfect for fiber optics communication.

If we talk particularly about PM optical fibers, they are used in special applications, such as fiber optic sensing, slab dielectric waveguides, interferometry, fiber optics communication, polarization-sensitive systems, and more where it is a requirement to maintain the polarization state of the incoming signal.

Did you know that optical fibers are also used to connect many fiber-optic elements?

While some fiber optic elements are typically made of fibers, other elements are made of different materials but are coupled to fibers. Here are a few examples of PM components:

- PM couplers that are used to combine light coming from different sources into one fiber

- Fiber Bragg gratings that are used as wavelength-selective reflectors in telecom and WDM applications

- Fiber collimators that can launch a collimated beam into a fiber

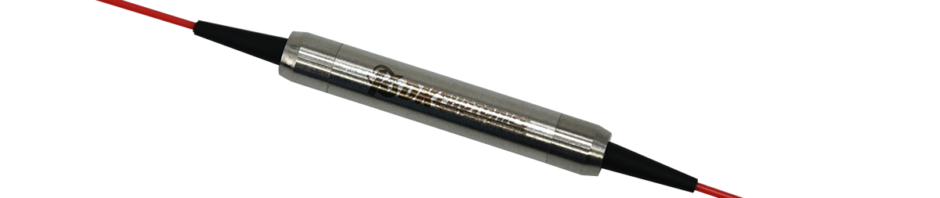

- Optical isolators, rotators, and circulators that are used for manipulations depending on beam polarization

Most PM components use PM optical fibers in one way or another; they are either made of PM optical fibers or are connected using PM fibers.

By now, we hope you understand the need for optical fibers in the industry and their importance.