Polarization Maintaining Isolator is also known as Fiber Optic Isolator which allows light to travel only in one direction. For any state of polarization, it minimizes the back reflection and back scattering in the reverse direction. It is a two port micro-optic device built with PM panda fiber. Polarization Maintaining Isolator is used widely in amplifier systems, fiber optic systems, and lasers. It prevents unwanted feedback into an optical oscillator and the device operations are dependent on the Faraday’s effect turn.

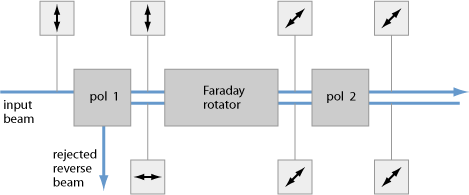

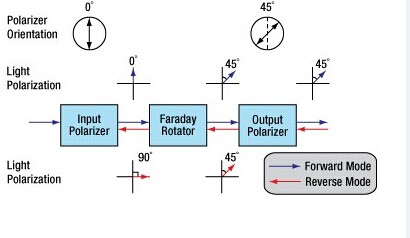

Faraday rotator is the main component of the optical isolator. The polarization dependent isolator mainly consists of 3 parts like an input polarizer, a Faraday rotator, and an output polarizer. The output polarizer is known as the analyser. Input polarizer vertically polarizes the light traveling in the forward direction. Using the analyser, the light traveling in the backward direction becomes polarized by 45°. The polarization dependent isolators are mainly used in free space optical systems as the polarization of source is maintained well by the system.

What are the devices in which the isolator is used?

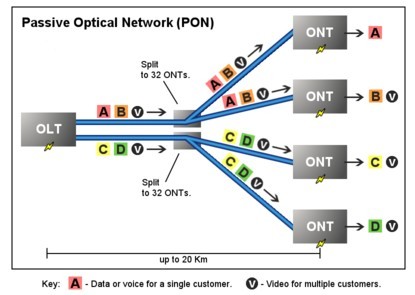

PM isolator is used in communication systems, polarization maintaining fiber-optic amplifier and instrumentation applications. Also, the insulating system is used in CATV Fiberoptic Links, Fiberoptic System Testing and Fiberoptic LAN System.

Here are the best features of polarization maintaining optical isolator –

- High Extinction Ratio

- High Return Loss

- High Isolator

- Epoxy Free Optical Ratio

- Low Insertion Loss

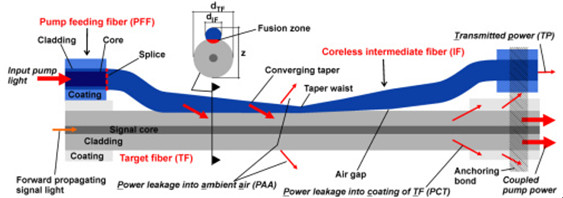

The light traveling in the forward direction is split by the input birefringent wedge into a vertical component which is called ordinary ray and a horizontal component is known as extraordinary ray. The rotator rotates both the o-ray and e-ray by 45°. Again the output birefringent wedge combines the two components. On either sides of the isolator, collimators are used and the beam is split & diverged in the isolated direction.

There are now companies who specialize in the manufacturing of the isolators for various applications. Based on the requirement of applications, isolators are manufactured precisely. Also, one can get the isolators online and the common PM Isolators available online are Polarization Maintaining Isolator 1310 & 1480 & 1550nm and Polarization Maintaining Tap Isolator 1310 & 1550nm.