Light polarization is very crucial for many applications such as optical sensors and optical gyro. The polarization ration varies, depending on the application. For example, optical sen sors and optical gyro requires high polarization extinction ratio.

sors and optical gyro requires high polarization extinction ratio.

There are different types of couplers available in the market. And each of them functions in a certain way. This means that a polarization coupler is designed to do a particular job. So the coupler you choose should be based on your requirement. If you have devices that requires high polarization ratio, fused PM coupler would do the job well. Or you can go with standard couplers readily available in the market.

What is polarization?

When the light goes into multiple directions, the light is not polarized. A device called coupler is used to control the directions of the light and lead it into a single direction. When the light is controlled into a single desired direction, it is polarized.

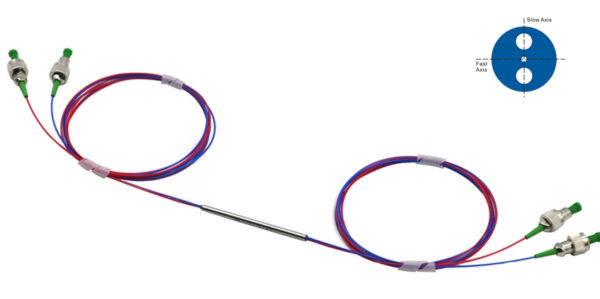

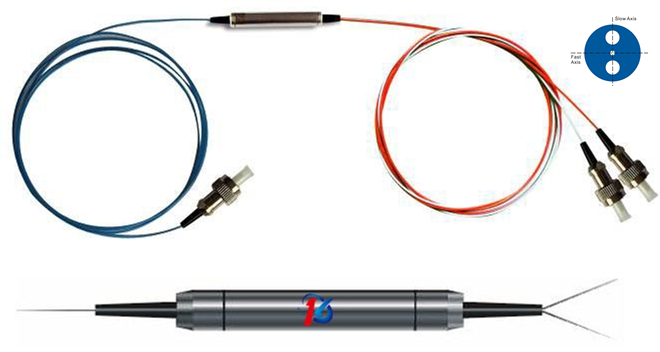

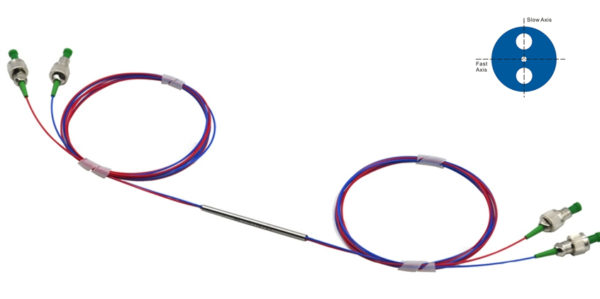

So the PM Fused Coupler is designed so, it can be used to split high power linearly polarized light into multiple paths without perturbing the line are state of polarization (SOP). The couple is also used as a power tap that allows you to monitor signal power in a PM fiber system without interfering with the line of SOP of the light passing through the PM fiber. The fused coupler has many applications. But most prominent ones include interferometers, power sharing in polarization sensitive systems, and signal monitoring in PM fiber systems.

Other applications of fused coupler include:

- Fiber Optic Instruments

- Fiber Amplifiers

- Fiber Sensors

- Coherent Detecting

- Research

So if any of these is what you are looking for a polarization coupler, then it is the fused coupler that you should go with. And this is because, compared to other options, the coupler comes equipped with far better features. Here are some of them for you to have a look at.

- Low Insertion Loss

- High Extinction Ratio

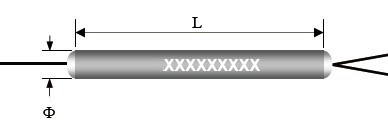

- Compact In-Line Package

- Available for Slow or Fast Axis Operation

- High Stability and Reliability

In fact, fused coupler has numerous benefits that you can see as you use it for light polarization and maintaining an optimum polarization. So to know more how fused couplers are best to maintain light polarization, all you need to do just get the one.

There are many suppliers of couplers in China. You can find a fused coupler with them. So all you should do is search for the coupler suppliers in China. And you can do that with little effort provided you have the internet access. Most renowned suppliers own a website as the part of the effort to build a strong online presence. But make sure you buy fused coupler for polarization maintaining from the supplier and of the make having a good reputation in the market and also provides a reliable customer support. So in case you have any problem later, you can get it fixed easily.