Where can WDM-PON go next?

Tag: pm isolator

WDM-PON technology-DK Photonics

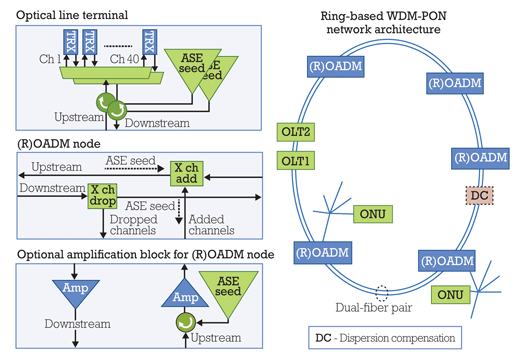

WDM-PON provides the dedicated bandwidth of a point-to-point network and the fiber sharing inherent in PONs. The architecture is somewhat similar to that of EPON and GPON; instead of the power-splitter approach used in TDM-PON architectures, WDM-PON uses an arrayed waveguide grating (AWG) filter that separates the wavelengths for individual delivery to the subscriber ONUs (see Figure 1).

A simple, plug-and-play implementation is based on wavelength-locked or tunable lasers. Self-tuning “colorless” ONUs can be used at the subscriber sites to simplify inventory and spare-part handling. Colorless optics not only simplify operations, but also reduce deployment costs, since they don’t need the expensive wavelength-stability components that traditional fixed and tunable optics require. There are multiple approaches to the colorless ONU technology.

In one approach, the wavelength of the ONU transmitter is controlled by injection of a “seed” signal into the transmitter (e.g., a wavelength-locked Fabry-Perot laser or reflective semiconductor optical amplifier). The seed signal injected into the transmitter could come from broadband ASE light sliced through the filters in the system or from a DFB laser array. In a self-seeding version of this approach, the seed light is provided by feedback of broadband light from the transmitter itself. The passive filtering of the seed light in the remote node determines the wavelength of the ONU transmitter.

In a different approach, the colorless ONU contains a singlemode optic coupler wavelength-tunable laser, which is able to tune to the appropriate wavelength that matches the remote node filter port.

Below 10-Gbps channel bit rates, the injection-seeded method provides a cost-efficient approach. As an example, a wavelength-locked Fabry-Perot transmitter can be integrated into an MSA SFP pluggable form-factor module, which enables the use of third-party CPE devices. A modified EDFA gain block in a 70×90 MSA form factor could be used to generate the broadband ASE light that’s used as a seed signal in the system.

At 10-Gbps bit rates, tunable-laser technology offers an alternative to the injection-seeded approach. The tunable-laser technology developed for the metro/long-haul market has matured significantly over the past couple of years and is able to give a good cost-per-bit ratio when high capacity is needed.

If the WDM-PON system is properly designed, then it’s possible to mix different transmission technologies. By following certain design rules during the installation of the WDM-PON system, it’s possible to allow step-wise channel upgrades to higher bit rates when the demand arises. These design rules ensure that channel OSNR requirements will be met in the presence of reflections and that inter-channel crosstalk is avoided. The result is an open and flexible access network that can support many applications and services over the same infrastructure. WDM-PON thus becomes an optical option for the access network as and where it makes sense.

Given its ability to help service providers cope with current bandwidth demands as well as the next potential broadband access bottleneck, WDM-PON/ 100GHz DWDM Module is becoming an important technology to consider in terms of its benefits and market timing. As with any emerging technology, service providers need to consider the optimal strategy for initial deployment of WDM-PON. That includes how they could use WDM-PON for additional network applications as the technology matures and its costs come down.

|

WDM-PON technology

|

|

FIGURE 2. Architectural scenario explored in the collaboration between Transmode and Deutsche Telekom Hochschule für Telekommunikation. |

The latest generations of WDM-PON systems are now gaining traction with operators around the globe for field deployment, lab trials, and evaluations. It’s clearly the early stage of WDM-PON deployments, but progress has started and 2014 looks to be a pivotal year for the technology.

WDM-PON is a key component in next generation access(1)

Many industry analysts believe that the increasing requirements for bandwidth scalability, quality of service, and support of the emerging traffic patterns required by video and broadcast standards will make copper networks insufficient for many high-bandwidth services in the future. Fiber availability is not universal, and the economics of new fiber deployments are often challenging; nevertheless, fiber will undoubtedly push deeper into access networks to support business services, mobile backhaul/fronthaul, multitenant buildings/fiber to the cabinet, and in some cases fiber to the home (FTTH), too. Yet today‘s fiber-based approaches, including TDM-PON/PLC Splitter and active point-to-point Ethernet, probably won’t meet the likely requirements of the next generation of bandwidth-intensive traffic, either.

WDM-PON is a passive optical networking approach — currently being developed by several companies — that can be used to more adequately address these challenges over fiber-based networks. A WDM-PON design can be used to separate optical-network units (ONUs) into several virtual point-to-point connections over the same physical infrastructure, a feature that enables efficient use of fiber compared to point-to-point Ethernet and offers lower latency than TDM-based approaches. A notable advantage of this approach is the combination of high capacity per user, high security, and longer optical reach. WDM-PON therefore is highly suitable for applications such as mobile backhaul or business Ethernet service provision.

Thus WDM-PON is poised to become the disruptive next generation access architecture. It will enable high-speed access for businesses, mobile backhaul, and eventually FTTH. WDM-PON also will enable operators to build converged networks and consolidate existing access networks, including potentially eliminating central offices to reduce cost while boosting performance.

There are several types of WDM-PON systems under development. They all have in common the use of passive, temperature-hardened DWDM optical filters in the remote node and colorless ONUs.

|

FIGURE 1. Basic WDM-PON architecture. |

DK Photonics – www.dkphotonics.com specializes in designing and manufacturing of high quality optical passive components mainly for telecommunication, fiber sensor and fiber laser applications,such as High Power Isolator,1064nm Components,PM Components,Pump Combiner,Pump Laser Protector,which using for fiber laser applications.Also have Mini-size CWDM, Optical Circulator, PM Circulator,PM Isolator, Fused Coupler,Mini Size Fused WDM.More information,please contact us.

Planar Lightwave Circuit Splitters Market Forecast

Fiber-to-the-Home deployment dominates the PLC splitter marketplace…

Aptos, CA (USA) – February 20, 2014 — ElectroniCast Consultants, a leading market/technology consultancy, today announced the report release of their market forecast of the global consumption of Planar Lightwave Circuit (PLC) splitters used in Fiber Optic Communication Networks.

According to the ElectroniCast market study, the consumption value of component-level (compact device) PLC splitters reached $529.6 million in 2013. PLC splitters will continue to contribute an important role in Fiber to the Home (FTTH) networks by allowing a single passive optical network (PON) interface to be shared among many subscribers. PLC splitters are available in compact sizes; therefore, they can be used in aerial apparatus, pedestals or in-ground as well as rack mount or other module-based value-added product. Installation is simple using a variety of connector types or fusion splicing.

“The PON-based Fiber-to-the-Home network application dominates the worldwide PLC splitter consumption value in 2014,” stated Stephen Montgomery, Director of the Fiber Optics Components group at ElectroniCast Consultants.

“The American region is forecast for flat annual growth (just over 1%); however, the EMEA region is set for 7% per year and the APAC region is forecast to increase at 15% per year, for the component-level PLC splitters, during the 2013-2018 timeframe cover by the ElectroniCast study,” Montgomery added.

DK Photonics – www.dkphotonics.com specializes in designing and manufacturing of high quality optical passive components mainly for telecommunication, fiber sensor and fiber laser applications,such as PLC Splitter, WDM, FWDM, CWDM, DWDM, OADM,Optical Circulator, Isolator, PM Circulator, PM Isolator, Fused Coupler, Fused WDM, Collimator, Optical Switch and Polarization Maintaining Components, Pump Combiner, High power isolator, Patch Cord and all kinds of connectors.

62.5/125 um Vs. 50/125um Multimode fiber Information

We have created this page to illustrate the very basic differences between 62.5 and 50/125 multimode fiber in selecting a patch cable for your existing cable plant.

The key thing to remember is to always use a patch cable of the same type as the cable that you are connecting to. It is virtually impossible to tell the difference between the two fiber types (62.5 and 50/125) by looking at the bare fiber* or the connectors*. Usually, this information will be written on the cable’s jacket.

The photos above illustrate that the outer diameters of the two fiber types are the same. What is different is the size of the center light carrying core of the fiber. You cannot see the fiber’s core without a microscope*. Therefore, you must rely on the writing that is on the fibers jacket to determine what type is.

Severe losses of light can occur when you try to match 50/125 and 62.5/125 fiber, as the illustration on the left shows.

* CAUTION: Never look directly into a fiber cable’s end face or into the ferrule of a connector (with fiber present) as there may be dangerous laser light present.

NOTE: This page was designed to help you know the difference between 62.5 and 50/125 fiber for the purpose of purchasing patch cables and products to connect to existing installed cabling. This page was not designed to provide information on choosing between the two types fiber for new installations.

Pump and signal combiner for bi-directional pumping of all-fiber lasers and amplifiers(5)

4.3 Simulations for the loss mechanism of the fiber combiner

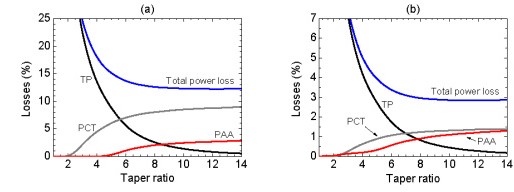

As already discussed in Section 2, the total 1064nm high power isolator loss is the sum of TP, PAA and PCT (Fig. 1). In this section we will quantitatively determine the power fraction of the different loss mechanisms to gain a better estimate of the resulting thermal load of the fiber combiner. To understand this approach, we first discuss the effect of the different loss mechanisms. The TP pump power loss is less critical, because this power fraction can be easily removed from the fiber component via the IF. The PAA is also less critical, since this power fraction can be handled by an air or 100W 1064nm high power isolator housing. The most critical pump power loss, PCT, is caused by NA-mismatched light, which couples into the coating of the TF and damages the fiber coating at a certain power level.

Fig. 4 The loss mechanism and the total pump power loss of the fiber combiner for (a) a TL of 5 mm and (b) a TL of 20 mm at different taper ratios. The losses in percent were calculated with respect to the total input pump power. Please see Fig. 1 for TP, PCT and PAA.

and 4(b) shows the three different pump power losses (TP, PAA, PCT) and the total pump power loss as a percentage of the input pump power for TL of 5 and 20 mm, depending on the TR. In the simulations the core NA of the PFF was 0.22 and fully filled pump light condition of the PFF core was assumed. It should be noted that for comparison, the axis of ordinates in Figs. 4(a) and 4(b)are scaled differently for a more comprehensive presentation of the results. In general, it can be seen that the total and individual losses are larger for a TL of 5 mm compared to a TL of 20 mm. For both TLs it turns out that the TP-fraction decreases and the PCT-fraction as well as the PAA-fraction increases with TR. As a result, the total power loss decreases with increasing TR. A closer analysis of the PCT-curve reveals that PCT loss does not exist below a TR of 2, since the 3 Port Polarization Maintaining Optical Circulator input NA of 0.22 will be approximately increased by the factor of the TR [18], and therefore cannot exceed the cladding NA of the TF of 0.46. Thus, the fraction of PCT can be reduced by choosing a low TR with a still acceptable total power loss. This means that the TR must be carefully adapted to satisfy the trade-off between a high pump coupling efficiency and a low power fraction of PCT to avoid optically induced damage of the fiber component during high power operation. This must always be accompanied by a sufficient converging taper length.

For example, if the TR is set to 7 for a TL of 5 and 20 mm, respectively, the theoretical PCT is 7.7 and 1.2% of the input pump power. The PCT value of 1.2% at a TL of 20 mm can be further reduced to 0.6% by changing the TR from 7 to 4 in conjunction with an acceptable total power loss of just 5%. Hence, if 1 kW of input pump power is assumed, the resulting power handling for the coating of the TF and the pump light stripper can be reduced from 77 W (TL 5 mm, TR 6) to 6 W (TL 20 mm, TR 4) by adapting the TL and the TR.

The simulations indicate that the minimum total power loss cannot be reduced below 2.7% for a TL greater than 20 mm up to a TL of 50 mm and a FL of 1.99. One reason for the residual losses can be pump light rays with a Polarization Maintaining Fused Coupler, which propagate along an unfavorable plane of the IF and do not enter the fusion zone. These rays leave the waveguide (PAA) structure after sufficient bounces along the lateral taper surface. In addition, rays with an extremely low NA, and consequently less bounces with the lateral surface of the converging taper portion, can occur in the form of TP. Furthermore, longer TLs lead to an increased probability that some rays will reverse couple from the TF into the IF.

Moreover, the simulations reveal that a lower FL-value, which means stronger fusing of the fibers, leads to a decrease of the total power loss. The exact reduction of the total power loss depends on the fiber and taper parameters. For a TL of 20 mm and a TR of 6, the simulated total power losses could be reduced from 4% to 2% when decreasing the FL from 1.99 to 1.93. The simulations indicate that for FLs below 1.93 the total power loss increase again.

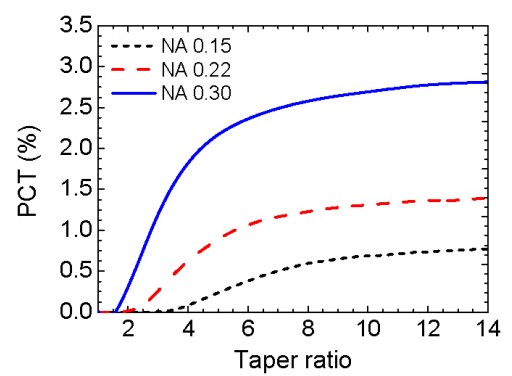

4.3.1 Impact of pump light input NA on the power leakage into the coating of the TF (PCT)

The simulations in Section 4.2, Fig. 3(b) showed that a sufficient TL leads to pump coupling efficiencies of more than 90%, almost independent of the pump light input NA. Considering the losses, the simulation also shows that the PCT-fraction is strongly influenced by the pump light input NA. Figure 5

Fig. 5

(PCT) to the total input pump power against the taper ratio for a TL of 20 mm.

clearly reveals that for a TL of 20 mm and a TR of 6, the PCT-fraction increases by about 6 times for a NA of 0.3 compared to a NA of 0.15. Hence, it is possible to achieve almost the same coupling efficiency for a pump light input NA of 0.15 and 0.3 (see Fig. 3(b)), but with a significant difference in risk of optically induced damage to the fiber component. However, PCT can be further reduced by increasing the TL.

Pump and signal combiner for bi-directional pumping of all-fiber lasers and amplifiers(4)

4. Simulations and experiments for a fiber combiner with a single pump port

The ray tracing simulations were carried out with the commercially available software Zemax (Radiant Zemax, LLC) in the non-sequential mode. Detailed information about ray tracing in tapered cylindrical fibers can be found in Ref [16] and [17]. The ray tracing method is applicable due to the large cross sections of the employed fibers compared to the applied wavelength of 976 nm. The 3-dimensional simulation model of the fiber combiner was based on the setup depicted in Fig. 1 with the approximation of a parallel fiber arrangement of the IF and TF. For the PFF a fully filled condition was always assumed, meaning that all possible pump light rays, independent of the NA and the transversal position in the fiber core, carry equal power. For the geometrical shape of the taper in the longitudinal direction, a simplified linear shape was assumed in the simulations, instead of the measured parabolic shape. As already mentioned, the FL was set to 1.99.

4.1 Simulations of the pump coupling efficiency

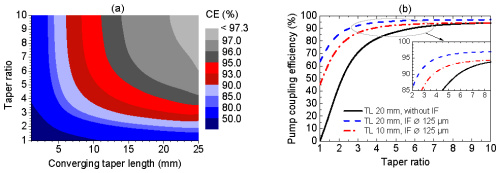

The pump coupling efficiency in dependence of the converging taper length (TL) and the taper ratio (TR) of the IF for a 1064nm high power isolator with an NA of 0.22 is depicted in Fig. 2(a)

Fig. 2 (a) Pump coupling efficiency (CE) with respect to the taper ratio (TR) and the converging taper length (TL) and (b) a comparison of the pump coupling efficiencies without intermediate fiber (IF) and with IF for different fiber parameters, IF Ø: IF cladding diameter.

. The simulations show that an increasing TL leads to higher coupling efficiencies at a constant TR. For example at a constant TR of 6 a TL of 5 mm leads to a theoretical maximum pump coupler coupling efficiency of 86%, whereas for a TL of 20 mm 96.4% were calculated. Furthermore, Fig. 2(a) shows that the TR can be reduced, if the TL is increased to maintain a certain coupling efficiency level. For instance, for a TL of 20 mm, a coupling efficiency of 85% can already be obtained at a TR of 2 instead of a TR of 5.5 at a TL of 5 mm. The improved coupling behavior at longer TLs can be explained by the increasing number of bounces of the pump light rays at the lateral surface of the converging taper portion. Hence, for shorter TLs it is necessary to taper more than for longer TLs in order to compensate for the shorter interaction length of the converging taper portion with the TF. The maximum theoretically obtainable pump coupling efficiency was limited to 97.3% due to different loss mechanisms, which will be discussed in Section 4.3.

In the following section we discuss the impact of the intermediate fiber on the pump coupling efficiency and the taper parameters. Thus, for comparison the fiber combiner was also simulated without the IF, which means that the tapered PFF was directly connected to the TF, assuming the same FL and also a NA of 0.22. Figure 2(b) illustrates that the coupling efficiency can be increased and the TR reduced, if an IF is inserted between the PFF and the TF. For a TR of 2.5 at a TL of 20 mm the coupling efficiencies with and without IF are 61.2% and 90.1%, respectively. The moderate coupling efficiencies without the employment of an IF at low TR can be explained by the presence of a depressed refractive index of the cladding of the PFF, blocking the power transfer from the IF to the TF, as already discussed in Section 2. Thus, without IF, the pump light rays with a low NA cannot escape from the core of the PFF, and a considerable fraction of power will be transmitted via the diverging taper portion. A further increase of the pump light NA, due to the increase of the TR up to 10 at a TL of 20 mm for the PFF and the IF, results in a successive approximation of the Polarization Maintaining Optical Circulator efficiencies. However, even at a TR of 10 and a TL of 20 mm (with IF) a 2.5% higher pump coupling efficiency can be obtained. That means for a hypothetical available input pump power of 1 kW, a reduction in power loss of 25 W can be essential to prevent thermal damage of the fiber combiner. Additionally, it must be taken into account that a TR of 10 corresponds to a considerable reduction of the mechanical stability due to the fiber diameter tapering from 125 µm to 25 µm. Furthermore, Fig. 2(b) clearly shows that the insertion of an IF with a TL of 10 mm already yields better pump coupling efficiencies than a PFF with a TL of 20 mm, especially for low TR.

A further increase of the pump coupling efficiency up to 97.8% can be realized by inserting an IF with a TL of 20 mm and diameter of 105 µm, which is perfectly adapted to the core diameter of the PFF, and thus, no pump brightness loss occurs. Note that for all of the following simulations and experiments, we only used the fiber component containing an inserted IF with a cladding diameter of 125 µm.

4.2 Simulations for the impact of the pump light input NA on the pump coupling efficiency

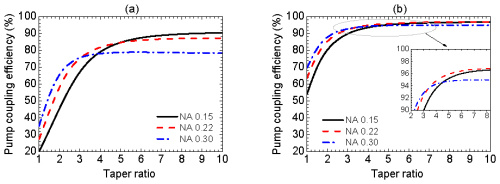

In the next simulation step we figure out, how the pump coupling efficiency changes with the pump light input NA depending on TR and TL. For these simulations three types of PFFs with a core NA of 0.15, 0.22 and 0.30 were investigated, assuming for each PFF a fully filled pump light condition. The TR was considered in the range from 1 to 10 at a TL of 5 mm

Fig. 3 Pump coupling efficiency with respect to the taper ratio at a converging taper length of (a) 5 mm and (b) 20 mm for a PFF with a pump light input NA of 0.15, 0.22 and 0.30.

) and 20 mm (Fig. 3(b)). From both figures it can be seen that at lower TRs the coupling efficiency increases with NA, since the pump light rays with a higher NA have more bounces with the lateral surface of the converging taper portion. However, the pump coupling behavior changes with increasing TR, since a TR of much higher than 2 leads to pump light rays with a NA far above 0.46, which cannot couple into the TF, if the TL is too short. The occurring pump power losses will be discussed in Section 4.3. E.g., for a low TL of 5 mm and a TR of 7 the coupling efficiency for an input NA of 0.15 was simulated to be 10% higher than for an input NA of 0.30. In contrast, with a longer TL of 20 mm the coupling efficiency seems to be less sensitive to variations of the pump light input NA. Thus, it appears that for the combiner design, the pump coupling efficiency should not be significantly influenced by the pump light input NA in the range of 0.15 to 0.30, if a sufficient TL is considered.

If the pump light input NA gets closer to the NA of the TF of 0.46, it can be advantageous to use a straight IF portion in addition to the converging taper to obtain a highly efficient pump light transfer into the TF as described in Ref [13]. An alternative approach to the straight IF portion is an increased TL, i.e. for a pump light input NA of 0.46 a theoretical pump coupling efficiency of about 90% can be achieved, if the TL is at least 40 mm.

Pump and signal combiner for bi-directional pumping of all-fiber lasers and amplifiers(2)

2. Optical design and relevant ray paths of the fiber combiner

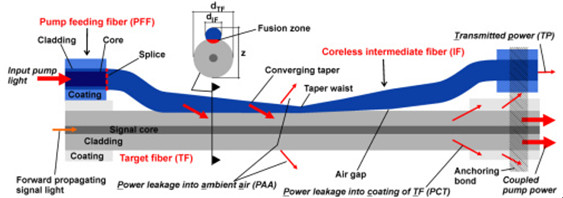

A schematic side view of the side-pump combiner consisting of a pump feeding fiber (PFF), a coreless intermediate fiber (IF) and a target fiber (TF) is shown in Fig. 1

Fig. 1 Schematic side view of a side-pumped double-clad fiber including important ray paths.

. The diameter of the PFF core and the cladding was 105 and 125 µm, respectively. The NA of the pure silica PFF core used in the simulations was 0.15, 0.22 or 0.3 and, therefore, the refractive index of the PFF cladding was depressed in comparison to the refractive index of the PFF core. The cladding of the PFF was surrounded by a polymer coating only for mechanical protection of the fiber. Therefore, the PFF preserved the same waveguide properties after removal of the polymer coating. In the case of side-pumping without an IF, the higher refractive index of the core of the PFF would suppress the pump power transfer into the TF as long as the PFF is untapered. An increase of the NA of the pump light due to tapering of the PFF would result in an increase of the pump power transfer, though only for rays that exceed the NA of the PFF core. Thus, it is especially difficult to couple pump light rays with a low NA into the TF. Unfortunately, this type of PFF is typically used as high power delivery fiber of pump diodes. To overcome this problem, without removing the glass cladding of the PFF, a coreless IF was inserted in the fiber combiner setup. At first the ~30 cm long IF with a cladding diameter of 125 µm was fusion spliced to the PFF. The IF had a NA of 0.46 due to the refractive index difference (Δn) between fused coupler silica and the outermost polymer coating. After removing the polymer coating (e.g. with acetone) along a certain section of the IF (~15 mm), the IF was individually tapered, and afterwards the converging taper portion was laterally fused with the TF. The fusion level (FL) is defined as FL=(2z)/(dIF+dTF), where dIF and dTF are the cladding diameters of the IF and the TF at a certain taper position, respectively, and z represents the distance of the fused IF and TF, as depicted in Fig. 1. The FL was experimentally determined by measuring dIF, dTF and z at different positions along the converging taper portion with an optical microscope. With this measurement an averaged very low FL of 1.99 was determined, which was also used for the simulations. The overlap area between the TF and the IF is defined as the fusion zone. In contrast to the converging taper portion, the diverging taper portion of the IF was not fused to the TF, but placed under a small angle to the fiber axis of the TF, resulting in a small air gap between the IF and the TF. The employed TF was a DC fiber with a core diameter of 25 µm (NA 0.06) and a cladding diameter of 250 µm (NA 0.46). The cladding of the TF was also surrounded by a polymer coating, except along the coupling region of the combiner. The low index coating had to match the mechanical and additionally the optical properties of the DC fiber. An anchoring bond was used to fix the fiber bundle on each side on a copper substrate. Figure 1 shows the anchoring bond only on the right-hand side without the copper substrate. Additionally, the anchoring bond served as a pump light stripper for rays which do not satisfy the NA criterion of the TF.

Before proceeding with a more detailed investigation with the aid of simulations in the next section, we will qualitatively discuss some important ray paths of the fiber combiner. Pump light rays guided into the PFF and entering the tapered portion of the IF increase in NA as long as the rays propagate along the converging taper. As a rule of thumb, the pump light input NA increases by a factor of the taper ratio (TR), which is defined as the ratio of the original fiber diameter to the diameter of the taper waist. Pump light coupling into the TF occurs as soon the rays enter the fusion zone. The converging taper portion increases the probability for pump light transfer into the TF, since the number of ray-bounces along the lateral surface of the IF increases. Particularly, pump light rays with a low input NA couple more efficiently due to the converging taper.

Pump light rays remaining in the IF, and consequently not coupling into the TF, can occur as transmitted power (TP: transmittedpower, Fig. 1) or power leakage into the ambient air (PAA: power leakage into the ambient air, Fig. 1). As long as the condition for internal total reflection is satisfied, the pump light rays are detected as TP, otherwise the rays escape into the ambient air as PAA. The angle of total internal reflection for the uncoated IF is 43.6°, since Δn between fused silica and air is 0.45 at a wavelength of 976nm pump laser protector, which means the IF can guide light up to a theoretical NA of 1.05. Of course, the NA cannot exceed 1.0. Therefore, pump light rays with a theoretical NA in the range of more than 1.0 up to 1.05 would experience total reflection in the case of an existing fiber endface. Pump light rays which exceed the theoretical NA of 1.05 occur as PAA.

For almost loss-free pump light coupling into the TF it is necessary that the rays enter the TF before they exceed the cladding NA of the TF of 0.46. This desired coupling behavior can usually be achieved by adapting the taper parameters. However, pump light coupling for rays with an NA far above 0.46 cannot be completely suppressed. Unfortunately, this pump power leakage couple into the coating of the TF (PCT: power leakage into the coating of the target fiber) and can damage it.

In summary, the input pump combiner will be divided into the coupled pump power and the losses including PAA, PCT and TP (Fig. 1).

Pump and signal combiner for bi-directional pumping of all-fiber lasers and amplifiers(1)

Abstract

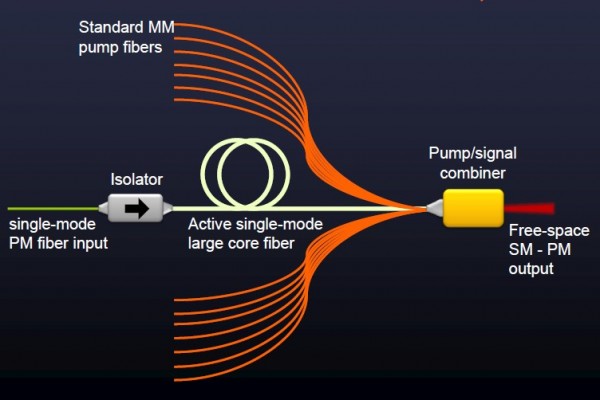

We developed an all-fiber component with a signal feedthrough capable of combining up to 6 fiber-coupled multi-mode pump sources to a maximum pump power of 400 W at efficiencies in the range of 89 to 95%, providing the possibility of transmitting a high power signal in forward and in reverse direction. Hence, the fiber pump combiner can be implemented in almost any fiber laser or amplifier architecture. The complete optical design of the combiner was developed based on ray tracing simulations and confirmed by experimental results.

1. Introduction

For the realization of compact, reliable, rugged and efficient monolithic high power fiber laser systems, the efforts of integrating all-fiber components have been increased in recent years [1,2]. A key component of a highly integrated fiber laser or amplifier system is a high power all-fiber signal and pump combiner.

The most common type of fiber combiner, a fused tapered fiber bundle (TFB) [3,4], is based on the fiber end face pumping technique and is probably the most sophisticated pump combiner capable of handling several hundred watts of pump power [5]. A TFB with signal feedthrough consists of a central input signal fiber, guiding the signal light, surrounded by several multi-mode fibers, guiding the pump light, and an output pigtail double-clad (DC) fiber which combines the signal and pump light in a single pigtail fiber. In order to match the diameter of the fiber bundle to the diameter of the output pigtail fiber, the bundle is slowly melted and tapered. After the tapering process the fiber bundle is cleaved around the taper waist and fusion spliced to the output pigtail DC fiber. However, tapering of the fiber bundle inherently involves increasing the numerical aperture (NA) of the pump light and a change of the mode field diameter (MFD) of the signal light. Hence, the necessary optical matching and mechanical alignment requirements between the tapered fiber bundle and the output pigtail DC fiber can lead to several drawbacks of the TFB structure: (1) less flexibility in the choice of input fibers that match the output pigtail DC fiber after the tapering process, (2) a slight mismatch or misalignment between the signal mode field diameters (MFD) of the tapered input signal fiber and the output pigtail DC fiber leads to a degradation of the beam quality, primarily in conjunction with signal insertion loss, and (3) in the case of a backward propagating signal, e.g. for a counter-propagation pumped fiber amplifier, the signal insertion loss (up to 10%) can cause damage to the pump diodes due to their insufficient isolation against amplified signal light.

A more promising approach to overcome these problems is side-pumping technology, which involves coupling the pump light via the outermost cladding surface into the fiber. The key advantage of this technology is the uninterrupted signal core, eliminating the need for an additional fusion splice in conjunction with signal mode matching. In recent years several proposals for side-pumping of DC fibers have been reported, such as V-groove side pumping [6], a mirror embedded in the inner cladding of a DC fiber [7] or side-coupling by an angle polished pump fiber [8]. However, for most of these side-pumping configurations it is difficult to reach the mechanical accuracy required for a stable and efficient pump light coupling.

A more rugged approach is a monolithic all-fiber combiner like the GT-Wave coupler [9], the employment of a tapered capillary around a multi-clad fiber [10, 11] or direct fusion of one or more tapered multi-mode fibers to the outermost cladding of multi-clad fibers [12–14]. In Ref [11] seven pump delivery fibers with a core diameter of 110 µm (NA 0.22) were combined and laterally coupled via a tapered capillary into a DC fiber with a core diameter of 400 µm (NA 0.46), which led to a combined pump power of 86 W with a coupling efficiency of ~80%. In Ref [13], direct lateral fusion of one tapered pump delivery fiber with a core diameter of 200 µm (NA 0.46) to a DC fiber of 250 µm (NA 0.46) led to a coupling efficiency of 90% at a pump input power of 120 W, furthermore, a pump delivery fiber with a diameter of 400 µm (NA 0.46) was used to couple a pump power of 300 W with an efficiency of 85% into a DC fiber with a diameter of 400 µm (NA 0.46). These impressive coupling efficiencies for one pump port were achieved by use of a straight and a tapered fiber section, allowing for highly efficient coupling of pump light rays with a high numerical aperture. Thus, in Ref [13] the impact of the straight fiber section on the side-pump coupling process was discussed. However, a review of the literature reveals that the impact of the fiber and taper parameters on the pump coupling behavior as well as the loss mechanism have not yet been investigated in detail for side-pumped combiners based on direct fusion of one or several tapered multi-mode fibers to the outermost cladding of a DC fiber.

We report detailed simulations and experiments for a component which combines up to 6 multi-mode fibers with a core diameter of 105 µm (NA 0.15 or 0.22) into a DC fiber with a cladding diameter of 250 µm (NA 0.46) via side-coupling. Firstly, we explain the principle of the optical design of the fiber combiner. For a fiber combiner with a single pump port, the achievable pump coupling efficiency and the corresponding loss mechanisms were investigated. For multiple pump ports, the simulations and experiments showed that with each additional pump port, the taper parameters need to be adjusted in comparison to a single pump port configuration. These simulation results can also be used as an estimation for fiber combiners, which combine one or several multi-mode fibers with a core diameter of 200 µm (NA 0.22) into a DC fiber with a cladding diameter of 400 µm (NA 0.46). Therefore, this work covers two important fiber combiner types, since active fibers with cladding diameters of 250 or 400 µm are typical sizes provided by fiber manufacturers and used for continuous wave and pulsed laser systems. In addition, we also investigated the signal feedthrough of the combiner. We demonstrated a low signal insertion loss, maintenance of an excellent signal beam quality and an efficient isolation of the pump diodes against signal light in the case of a reverse propagating signal. The preservation of the signal light properties by the fiber combiner was utilized in Ref [15] for the realization of a counter-propagation pumped single-frequency fiber amplifier with an amplified signal power of 300 W.

What is Pump Laser Protector, Where is the Pump Laser Protector use?

The Pump Laser Protector (also called Pump Protection Filters) is a passive component which allows maximum transmission from a discrete fibre-coupled pump laser diode and blocks parasitic signals around the centre wavelength of the laser from being reflected back into the laser.

Single-emitter laser diodes are highly regarded for their long term reliability. However, these devices are very sensitive to backward propagating light within the delivery fiber. Backward power imaged onto the diode material, as small as 5% of the pump diode output, can cause accelerated diode degradation and, in the majority of cases, catastrophic failure.That is why we need Pump Laser Protector.

DK Photonics offers filter technology that provides protection to pump diodes under these conditions (up to 50 dB Backward Signal Attenuation). Splicing these filters to the pump output fiber rejects unwanted light before it reaches the diode.

Multimode Pump Protection filters are available for a wide range of standard light emitting diodes. Fiber pigtails are 105/125 micron, with both 0.15 and 0.22 NA cores and 50/125 or 62.5/126 MM fiber available. Operating wavelengths cover the majority of diode laser lines (915 nm, 940 nm, 960 nm and 976) and maximum power handling is 25W without water-cooling.DK Photonics recently released a new type of Pump Laser Protector up to 200W handling power with water-cooling technology. And also have SingleMode Pump Laser Protector with Hi1060 fiber for 976nm fiber laser.

If you do not see a Pump Laser Protector from the standard configurations that meets your needs, we welcome the opportunity to review your desired specification and quote a filter best suited to your application. Different pump/rejection wavelengths or fiber pigtail can be accommodated.

DK Photonics – www.dkphotonics.com specializes in designing and manufacturing of high quality optical passive components mainly for telecommunication, fiber sensor and fiber laser applications,such asDK Photonics' promotion products including:High Power Isolator,1064nm Components,PM Components,Pump Combiner,Pump Laser Protector,which using for fiber laser applications.Also have Mini-size CWDM, Optical Circulator, PM Circulator,PM Isolator, Fused Coupler,Mini Size Fused WDM.More information,please contact us.