With time, the need for Polarization Maintaining Components is increasing in telecommunications and other related industries. And it’s because Polarization Maintaining Components make the process easy for these industries and deliver quality results.

Years ago, only a few components were available. Manufacturers were not so aware and even the industry owners were not so keen. Things were going in the right direction with the limited Polarization Maintaining Components. But, today, things have changed and there are many Polarization Maintaining Components in the market, making the functioning and process easier for the industry owners.

Products are many but some are commonly needed by the industry owners. A few names in this list are PM isolator, PM Coupler, and PM Circulator. In this post, we will discuss these Polarization Maintaining Components.

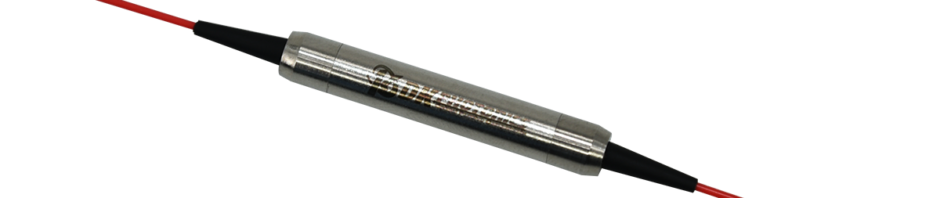

PM isolator

In every PM isolator, you will find an optical fiber inside. The fiber inside is a thin strand made of pure glass. The isolator or the optical fiber inside it works on the “total internal reflection” principle. It acts as a guide for the light wave over long distances. The working of a PM isolator is very effective when the light waves try to pass between varying media.

A PM isolator is used in different applications but majorly, it is used in communication systems, instrumentation applications, and polarization-maintaining fiber-optic amplifiers. Other than this, the PM isolator is used in fiberoptic system testing and fiber-optic LAN system, and CATV fiberoptic links.

PM coupler

It’s a device used for combining or coupling light from two or more input fibers into one output fiber. The PM coupler consists of an input section at one end and an output section at another end. Simple to understand, a PM coupler converts input light from different fibers to a single output fiber. The process becomes simple.

The biggest advantage of the PM coupler is that its output section comprises an optical fiber, which can be made in appropriate lengths and easily tapered. Due to this, this component can be used in two separate functional units. Other than this, a PM coupler has higher longevity and is affordable to all users.

PM circulator

The role of a PM circulator is to separate optical power traveling in opposite directions in one optical fiber. Also, it is used to achieve bi-directional transmission over a single fiber. The PM circulator is highly suitable for use in advanced communication systems and fiber-optical sensor systems because of the high isolation between the input and reflected optical power and low insertion loss.

Other than this, a PM circulator provides high reliability and excellent optical performance. This is why it is a Polarization Maintaining Component in telecommunications, fiber optic sensing, bio-medical, and photonics research.

Contact DK Photonics to buy Polarization Maintaining Component

We are one of the leading manufacturers of Polarization Maintaining Components globally. We follow a strict manufacturing princess with advanced production equipment in an excellent production environment. This is why you will get good quality products with quick delivery. The best part is we customize the components on demand.